+49 2154 – 88 29-10

Dieckers GmbH und Co. KG

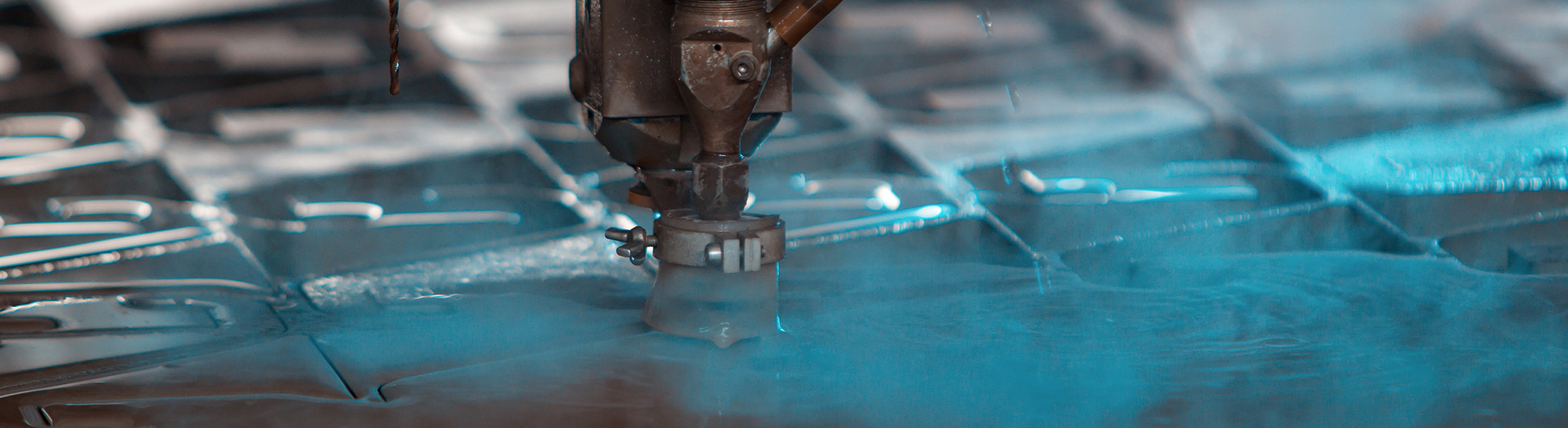

Waterjet cutting

Waterjet cutting using a high-pressure water jet is today an established process for cutting a wide variety of materials. Waterjet cutting can be employed for a wide variety of purposes. Differing processes are employed for the different materials, e.g. pure waterjet cutting and abrasive cutting. One significant advantage over conventional cutting methods is that no heat is generated during cutting. Despite a pressure of around 4,000 bar in the majority of cases, the material being cut doesn’t suffer any heat damage.

Further advantages include:

- No deformation of the material

- Low environmental impact: no smoke or steam

- No resharpening of the tools necessary

- Hardly any post-processing necessary as there are no rough edges

- Cut can start at any position